Calculating the heat loads

It is important to choose the right heat output of your wood burner. A right decision can give your future enjoyment of your burner and its running costs. The following guidelines will help you to decide which heat output is ‘ideal’ for your requirements. However, the ‘ideal’ temperature you want to achieve is always going to be a matter of personal preference. Here are some considerations you should bear in mind…

Choosing a big burner and reducing the fuel load to compensate means that the fire-chamber may not reach the correct operating temperature and thus the body may not be able to radiates the heat in a traditional wood burner or convect the heat in a contemporary convection wood burner. What you’ll get is a lackluster fire and poor heat output. Reducing the temperature will also make the flue gases rise slower and thus could create problems with creosote and condensates. You are going to have problems also by keeping the glass clean as a low temperature reduces the effectiveness of the glass air wash system. Finally from an environmental viewpoint choosing a big burner and then reducing the fuel load has as a result to producing more smoke and more pollution.

On other hand, choosing a burner which is too small and then having to stoke it up to get warm on very cold days could potentially permanently damage your burner and flue system through over-heating the wood burner and the flue components.

How to work out the burner output you need

Biogeography Map of Europe

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Biogeography Map of Greece

|

|

|

|

|

|

|

|

Firstly, select your area of residence and then, multiply the Length x Width x Height (in meters) and choose one of the three categories listed below, depending on your interpretation of the insulation standard of the space where the stove will be operating. This will provide you with a good estimate of the heat output that you would need from your wood burner and taking into account the considerations outlined in the section above this should help you arrive at the ideal output for your requirements.

| INSULATION | DESCRIPTION |

|---|---|

| Poor | No double glazing or cavity wall insulation |

| Reasonable | Some double glazing or cavity wall insulation |

| Highest | State-of-the-art insulation |

Typical Calculation

Choose area: Mediterranean

L5.00m x W4.90m x H2.95m = 72.28m3

Choose insulation: Poor

Result: 4.82kw

Therefore the output of the stove that you would need would be approximately 5.00kw (rounded up) and no more than (4.82kw + 1kw = 5.82kw most bigger near stove 6.00kw)

This is based on the standard industry calculation using a wood burner to heat a space to a comfortable temperature (22ºC) when it’s 0ºC outside.

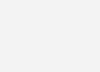

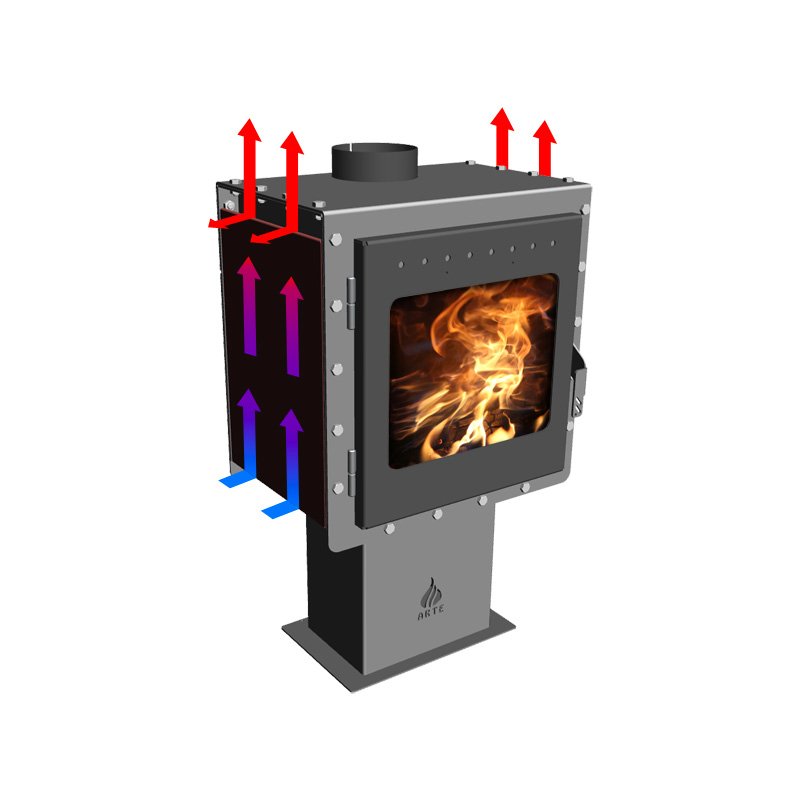

Convection air-flow or radiation heat

Many aspects of the design of wood stoves are related more to aesthetics and personal preference than to performance. However, there is an important performance difference between stoves that deliver their heat to the room by direct radiation compared to those that deliver heat by convective air flow.

Radiation

Radiation is when heat is emitted as invisible light. In a wood burner, radiation is emitted from the flames. These rays travel through the air until they hit a material which absorbs them. This material will become warmer as a result.

This type of heat is ideal in a room with a high ceiling (since this type of heat will not rise up as quickly and be lost in the ceiling space), in buildings with plenty of draft, or simply if you are looking for rapid direct heat from your burner. Cast iron stoves and those with heavy steel plate surfaces are of the radiant type.

It’s important that furniture be placed at a safe distance from the wood stove in order to avoid being damaged by the radiant heat. Also heat shields should be used to protect the flooring and walls, providing a better amount of clearance for the hearth appliance.

Convection

Convection is when the air around the stove becomes warm, expands and rises. If the stove has a convection chamber, the air between the stove and the plates heats up more quickly. The heated air will rise and it will be displaced by cooler air, which will then warm up from the stove and rise up to follow. This cycle creates a flow throughout the room.

The hot air gathers under the ceiling and it will be possible to blow this down towards the floor using a ceiling fan. Convection takes a little bit longer to heat up the room, compared with radiation. For these reasons also you can use a convection burner with a blower fan to accelerate the heat cycle and as a result to heats up more quickly the area.

While the heating efficiency of radiant and convection stoves is about the same, there are advantages in using one or the other type depending on the details of the installation.

Example: a radiant burner is effective in a relatively open area where the radiant warmth is dispersed. A radiant burner in a small room will make people feel uncomfortably warm. The radiant heat is somewhat more difficult to distribute to other areas of the home. A convection burner, on the other hand, produces hot air which can be more easily distributed to other areas. You can sit quite close to a convection burner without feeling uncomfortably warm.

The Arte as leading wood burner manufacturer, include both radiant heat and convection heat, allowing for both speedy warmth and excellent circulation.

Certification

All the products distributed through the EU must have CE certification. This certification is awarded by certain organisations, both private and state, and which are authorised and notified by each state separately in the central catalogues of the European Union. These catalogues include the four-digit number of the notified organisation as well as the sectors and products which each organisation can certify.

Arte® does not only claim to have certified products but it proves it also. Our products are certified by the Termotest Consult laboratory under number 1999.The organisation which has given our company ISO certification is Q-CERT

The catalogues of notified organisations which award certifications can be found on the NANDO (New Approach Notified and Designated Organizations) site.

Why wood?

With proper forest management, burning wood does not deplete the earth’s resources. Heating with wood usually does not contribute to global warming. The young trees that replace the trees in your wood stove absorb carbon dioxide from the air.

Burning firewood releases only as much CO2 as the tree has absorbed from the atmosphere during its growth.

Wood rotting in the forest generates the same amount of CO2 as the same wood burning.

Besides being environmentally friendly, the heat from a wood stove warms you like the warming rays of the sun during the sunny winter days. It is the radiated heat that transmitted by electromagnetic waves in the infrared range. Even when the air is very cold you can feel the warm rays of the sun on your skin.

Another advantage to wood is that it is produced locally, which creates local employment, and more tax revenues stay in the province.

Wood burning & particulate matter

Heating with firewood is lately experiencing a powerful revival. Unfortunately, as wood burns it emits, not only heat and radiation, but also by-products of combustion such as the lately debated particle matter.

Although the burning of wood is an ecological alternative heating solution, it may constitute a risk if the combustion appliances (stoves, fireplaces, etc.) are not properly operated.

What is particulate matter?

Dust, as it is a natural component of air, is all around us. It is divided in coarse dust, visible to the human eye and fine, not visible dust. Particulate matter, are floating, microscopic particles which are part solid and part liquid. They do not fall to the ground immediately, but remain in the atmosphere for a certain time.

These particles (PM10) are less than ten thousandths of a millimeter in diameter, that’s ten times smaller than the thickness of a human hair, and can be harmful for a human’s entire respiratory system.

How is particle matter created and how can it be prevented?

Particulate matter is created from industrial and combustion processes and also from road traffic in the form of exhaust gases and particles resulting from wear of the road surface and tires. Source of particulate matter is also dust, resulting from agricultural activities, especially during drought. There are also natural sources like dust from deserts and pollen. All these floating particles can travel extremely long distances through air currents.

Burning wood can produce particulate matter in varying degrees. Its quantity and quality depends on the quality of the combustion, the fuel and also how each device operates. When dry firewood burns in a device equipped with innovative combustion control, the particulate matter emission are so low that don’t pose any threat to human health. When, either the firewood is not properly dried or the device is not properly equipped, the combustion is incomplete and produces large quantities of particulate matter and soot. The situation is aggravated when the device is used as an incinerator or when it is supplied with wood containing varnishes, resins, solvents or adhesives For this reason, you too should contribute in creating a better future, by ensuring that the device provides comfort and warmth without harming your health and the environment.

Burning wood, despite the particulate matter, is still the cleanest solution

Wood is a renewable energy source that, unlike fossil fuel, does not emit any additional carbon dioxide (CO2) when burned properly. Also, in relation to crude oil, the price is not particularly affected by the international markets. So, by using a heating device by ARTE@ you can feel comfortable and with a clear conscience as ARTE@ devices emit minimal particulate matter and thus wood heating is both an environmentally friendly and also an economic alternative.

A cleaner future by ARTE@

ARTE@ devices, with their innovative combustion process, reduce emissions to much lower levels than the thresholds laid down in Europe and worldwide. They also show high performance and at the same time contribute significantly to the maintenance of clean air.

Purchasing wood

Buying ready to burn firewood

Regenerated ready to burn firewood can be purchased from dealers:

- Stove-ready, stored for at least two years

- Pre-dried, stored for one year

- Fresh from the forest

The ideal residual moisture is 12 – 15% and should be no higher!

Whether you have cut your own wood or bought it, the important thing is: the wood should be dried for at least two years before it is burned

When purchasing, check-out the following:

- Is the fuel the right type and size for your stove?

- Are the logs green or seasoned? (Is there specified moisture content?) Consider how much space you need if drying your logs – you need space for at least one winter, preferably two).

- Some log suppliers supply by the “load” – what does this mean? Request a volume measurement in cubic meters.

- In some countries the wood sold by the m3 rather than by the kg

Indicative prices kg/m3 for different types of firewood with 20% humidity

| Type | (kg/m3) 1m3 stacked firewood length ~33cm | (kg/m3) 1m3 bulk (non-stacked) firewood length ~33cm |

|---|---|---|

| Beech | 453 | 306 |

| Olive wood | 583 | 394 |

| Oak | 450 | 304 |

| Pine | 349 | 215 |

- Where is the wood fuel coming from?

- Is the woodland sustainably managed, and reasonably nearby? (Have they been imported?)

- Hardwood or Softwood logs?

- Does the supplier offer a stacking service?

Storage

The full potential for heat will not be realized if you neglect the simple chore of piling and protecting your wood. Proper storage is essential to avoid moisture, bacteria, and insect problems in your home.

To avoid problems with insects and moisture, store the wood as far from your house as is practical. Do not store wood in your basement; one cord of wood can give off more than 550 liters of water. The basic rule is to hide the wood from water, but not from the sun or wind (Figs. 1 & 2). Green wood will dry slowly or not at all if unprotected, while seasoned wood left unprotected may become unseasoned.

Fig. 1

Fig. 2

There are three basic rules to follow when storing wood:

- Allow air circulation by piling one tier wide if possible;

- Protect wood from rain and snow by covering with a tarp or woodshed roof;

- Pile wood off the ground on scrap lumber or wooden pallets.

The time-honored way to cure wood is to buck, split, and stack wood off the ground for one full year. However, wood can generally be reduced to 20 per cent moisture content in two to three months. The ideal 10% to 15% may take longer (almost 18 months).

Thermal efficiency

Ο βαθμός απόδοσης ενός ξύλου δεν εξαρτάται μόνο από το είδος του, αλλά και από το ποσοστό υγρασίας του, καθώς και τη θερμοκρασία του χώρου καύσης.

Για αποδοτικότερη και μακρύτερη καύση, χωρίς εκπομπές βλαβερών ουσιών, τα ξύλα πρέπει να είναι στεγνά. Ιδανικά, το ποσοστό υγρασίας τους δεν πρέπει να ξεπερνά το 12% με 15%.

Αν η τιμή υπερβαίνει το 20%, η καύση δεν γίνεται σωστά, ενώ σε περίπτωση που το ξύλο έχει μόλις κοπεί, η υγρασία ξεπερνά το 60% με αποτέλεσμα αυτό να καθίσταται ακατάλληλο. Ο λόγος; Αδύναμη, χλομή φωτιά με πυκνό καπνό, άκαυτη πίσσα και κρεοζότο, που λερώνουν το κεραμικό τζάμι και τον καπναγωγό.

Είναι προτιμότερο να προμηθεύεστε τα ξύλα κατά τους καλοκαιρινούς μήνες και να τα αποθηκεύετε σε σκιερό και αεριζόμενο χώρο, ώστε να εξασφαλίσετε καλύτερη και ποιοτικότερη καύση το χειμώνα.

Wood types

Briquettes

They ignite very easy, and burn slowly. They are economically advantageous because you will burn smaller quantities compared to common firewood and they are easily stored. Also, you have less quantity of ashes vs. to wood.

Birch

Soft wood ignites easily with great thermal energy production. It produces less smoke and ash compared to other wood and burns silently. The same characteristics apply for lime and chestnut.

Beech

Hard wood ideal for firewood requires a high temperature to ignite. It weights a lot, it is dense and burns with a calm and long fire for a longer time. Best when well seasoned. The same applies for oak, but seasoned for 2-3 years.

| Wood Type | Heat capacity (Kcal/h – 1Kg) |

|---|---|

| Briquette | 5.000 |

| Birch | 4.800 |

| Walnut | 4.731 |

| Oak | 4.619 |

| Beech | 4.578 |

| Fir | 4.588 |

| Common Oak | 4.548 |

| Pine | 4.457 |

| Olive wood | 4.100 |

| Poplar | 4.022 |

The values are based on 15% residual wood moisture

Useful tips

- Always choose dry firewood. Any water present in the timber has to evaporate away before the wood will burn efficiently. To identify well seasoned wood, their radial cracks and bark should easily come off. You have the option to buy dry wood or green logs (if you decide to dry them yourselves).

- Avoid wood that pops (chestnut, conifers such as cedar, spruce and pine), as they may damage your burner or the smoke duct.

- Pay attention to the size of the woods. Good firewood must have been cut at least twice.

- You should prefer oak, beech, olive wood, hard wood with high density since they will burn for longer. A tone of hardwood logs will occupy a smaller space in comparison to a tone of softwood logs and the denser the wood, the longer it will burn meaning, less topping up required for your wood burner.

Chimneys and safety

The condition and functionality of your chimneys must be inspected by a chimney sweep or specialist before the ARTE® wood stove is installed.

(EN 13384-1 & EN 13384-2)

This will provide the optimal conditions for trouble-free heating.

Common chimney problems

- Retrofitting an old chimney: Frequently, old chimneys are too big for today’s wood stoves. That means the amount of air they draw is not proportional to the amount of heat the stove produces. A too-big chimney means you’ll burn more wood than you need, and likely spend more time than necessary on fire maintenance. You’ll need to install a “liner” stovepipe within the chimney. It should run the entire length of the chimney, and nowhere along its length should it be any bigger than the stove’s exhaust opening. But — before you go jamming pipe up the chimney — you should know how the chimney was built, and what sort of insulation it contains. The heat produced by a wood-burning stove is different from the heat produced by an open fireplace, and your chimney may not be up to the task without some work.

- Setting the stovepipe to minimum height requirements: A short chimney may look nicer (though that’s a matter of opinion), but it may not supply an optimal draft to the stove. Work with a professional to figure out the right stovepipe height for your stove.

- Running too much horizontal stovepipe: A venting system works best when it’s vertical. Some homeowners, rather than create chimney holes in the roof, run stovepipe out windows or through walls. But this is a very bad idea.

- Running the stovepipe along an exterior wall: This isn’t a safety issue so much as an efficiency issue. The stove will heat more of the house if the pipe travels up along an interior wall, so all the heat from the pipe stays in the house.

- Creating too many twists and turns: Venting systems should be direct and straight. Twists and turns in a stovepipe invite the buildup of creosote, and that raises the risk of fire.

Traditional

When first lighting the stove, a large volume of air is needed. When the stove is cold, you should leave the door open to the first latch so there is an air gap around it (or if you do not have a handle with two latch, 1 – 2cm ) for the first few minutes and open the primary & secondary air supply completely.

While the door is open, do not leave the stove unattended.

To form a reasonable bed of ash on the floor of the stove, you should use 1-2 kg of dry kindling at the initial lighting. If possible, maintain a 2-3 cm layer of ash on the floor of the combustion chamber for added insulation.

- Put 2-4 fuel tablets or 7-10 rolled up sheets of newspaper underneath 1-2 kg of dry kindling.

- Open the primary & secondary air

- After the fuel tablets/rolled up sheets have caught fire, leave the fire door ajar about 1 – 2 cm (or to the first latch of handle), so that the chimney draws well.

- When you can see that the chimney is hot enough to draw (after 5 – 10 minutes), close the door. If all the necessary conditions are met, a thick layer of embers will have been formed in the combustion chamber after another 15 – 20 minutes, and there will be a high temperature in the combustion chamber, which is necessary in order to be able to continue the combustion.

- If the condition in step 4 is met, place 2-3 pieces of wood with a total weight of 1.5-3 kg over the embers, with a distance of approximately 1 cm.

- Open the air supply to maximum, and close the door. The fresh wood will be lit within 2-3 minutes. If it does not light, open the door slightly to allow in enough air to ignite the wood. Close the door again once the wood has caught. Also close the primary air.

- Reduce the amount of secondary air to the desired position, and the optimal combustion will continue. Make sure that there is always enough air (oxygen) to maintain clear, lasting flames when, and after, reducing the amount of combustion air.

- Once the fire has been reduced to a thick layer of embers, a new portion of wood can be added by repeating steps 5 & 7.

Firing without releasing CO

- Open the primary & secondary air. If necessary, keep the door slightly open about 1 – 2 cm (or to the first latch of handle).

- Place 2-3 pieces of wood with a total weight of 1.5-3 kg and a length of 30-35 cm in/out on each side of the base. (Fig.A & Fig.B).

- In order to avoid sooting on the glass, it is important that the log is not placed adjacent to the glass on the product.

- Put 2-3 fuel tablets or 5-8 rolled up sheets of newspaper between these woods.

- Add some kindling wood (1-2 kg) in a criss-cross pattern on top. (Fig.A & Fig.B)

- Finally, place a medium-sized log on the top of the pile and light the tablets/newspaper.

- The maximum height of the pile of the wood should be just below the secondary air holes (Ermis). The holes must not be covered (Apollo).

- When you can see that the chimney is hot enough to draw (after 5 – 10 minutes), close the door and the primary air.

- Reduce the amount of secondary air to the desired position, and the optimal combustion will continue. Make sure that there is always enough air (oxygen) to maintain clear, lasting flames when, and after, reducing the amount of combustion air.

- Once the fire has been reduced to a thick layer of embers, a new portion of wood can be added. Stoke the stove frequently but only add small amounts of fuel, max 3 kg at a time. If the stove is filled too full, the heat created may cause extreme stress in the chimney. Add fuel to the fire in moderation.

Fig. 9A

Fig. 9B

Solutions

Wood does not ignite when stove is fired; fire just smoulders away; fire extinguishes:

- Open combustion air slide

- Kindling unsuitable

- Wood too damp

- Firewood too thick

- Ash drawer full

Heavy shooting in the firing chamber; heavy sooting on the window:

- Open combustion air slide

- Too little wood

- Firewood damp or too thick

Smoke escapes from the stove:

- assure adequate extraction in the chimney, light pilot fire

- provide for adequate supply of air