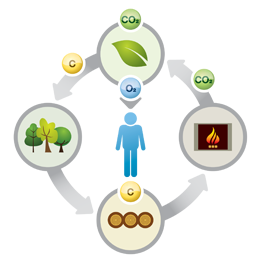

Combustion cycle

Those people who consider the impact of of their actions on nature will help future generations.

Given that trees mainly store the sun’s energy, heating with wood ties in harmoniously with the environment. When you burn wood in your boiler, CO2 is released which had been stored in the tree as it grew. If wood is not burnt in the boiler, but the tree is left to die in the forest, the same amount of CO2 is released into the atmosphere.

1. Carbon Dioxide is absorbed by the atmosphere during photosynthesis and is broken up into oxygen and carbon.

2. Carbon provides nourishment for plants to grow, while the oxygen released into the atmosphere by the plants is vital for man.

3. The wood we get from the trees is a mixture of carbon, water and various salts.

4. The burning of wood in the Arte fireplace provides secondary combustion, giving almost the perfect combustion by producing the optimum amount of carbon dioxide and heat.

5. The result of generating the optimum amount of heat and carbon dioxide is less consumption of wood (less fuel – more economical), which helps in the continuation of the tree’s life cycle since carbon dioxide is absorbed by plants while monoxide is not.

Explanation of symbols

C = Carbon

O2 = Oxygen

CO2 = Carbon dioxide

CO = Carbon monoxide

Secondary combustion

One of our objectives is to develop wood burners that burn cleaner and more economically than any other product in relation to the environment.

In traditional heating appliances, wood combustion is never complete. This has as results:

- low efficiency (Partial use of the calorific value of wood resulting in significant wastage)

- pollution (formation of carbon monoxide: CO)

C + O2 = CO2 + CO + θερμότητα

Thanks to the Double combustion technology applied to our fireplaces and wood stoves, the following reaction take place inside the burner:

Primary combustion:

C + O2 = CO2 + CO + heat

Double combustion:

CO + O2 = CO2 + heat

During the primary combustion of wood, heat and fumes of carbon dioxide, carbon monoxide and water vapors are produced.

During the secondary combustion, we add pre-heated oxygen at the upper part of the fire; as a result a re-ignition of the carbon monoxide starts, giving us a high thermal output, along with minimization of the operating costs and decrease in polluting emissions.

This way, we achieve the production of carbon dioxide and not monoxide which cannot be absorbed by plants.

Quaternary (fourth) combustion

Four points of combustion

For the burning of wood to be efficient it needs to pass through a process of primary, secondary, tertiary and quaternary combustion.

Primary combustion

This is the initial burning of wood at relatively low temperatures. During primary combustion, large amounts of creosote gas and soot are produced because of the water contained in the wood. Creosote holds 60% of the potential energy of the wood, but which is deposited as soot on the inside of the stove and chimney without emitting heat.

Secondary combustion

The combustion chamber is thus insulated, allowing the core temperature to rise – providing precisely the right amount of oxygen – to 600ºC which is the temperature at which creosote spontaneously combusts. A chain reaction then increases the temperature on the inside of the wood-burning stove from 600ºC to roughly 870ºC without the addition of any fuel. This, then, is secondary combustion.

Thus, the more correct secondary combustion we create, the higher the temperatures and the fewer residues we leave (gases and micro-particles). The vast majority of secondary combustions however take place on the upper part of the burner, near the flue exit. Therefore a large part of the increased temperature immediately exits to the outside space via the flue draught rather than entering the combustion chamber.

ARTE’s patented burner succeeds in providing us with optimum secondary combustion performance. A system of regulators and four vertical conductors with apertures arranged in such a way (Diagram 1 & Diagram 2) that it allows throughout the length of the conductors the right quantity of pre-heated air to enter the hot side of the combustion chamber as well as the air-wash system of the ceramic glass, permitting the fire on each side of the burner to receive the correct amount of pre-heated oxygen.

In this way, we succeed in transforming all the area of the burner and not just the upper part into an area of secondary combustion, thus dramatically its performance and respectively reducing the gas residues.

Tertiary combustion

Tertiary combustion occurs with the correct and coordinated burning of the carbon and ash remaining under the cast-iron grill. Carbon and ash contain large amounts of thermal energy, which when used provide a large amount of heat. The correct arrangement of holes inside such a hot space places the remains in such a way to lead to the almost complete burning of the material and the minimising of the ash which has collected at the bottom.

Quaternary combustion

The stove has an innovative quartenary combustion process. As hot gases move towards the exit of the combustion chamber they pass through a 3mm stainless mesh plate [diagram. 1]. When the soot and creosote particles which have escaped the secondary and tertiary come into contact with this extremely hot plate they ignite. This means less fumes and greater heat for the space we are heating.

Environment and the company

The environment plays an important role at Arte.

We not produce only some of the most sophisticated and environmentally friendly wood-burners. But we try as a company to have the smallest eco footprint, also. We have done it, long before it became fashionable. For this reason we have a very strictly environmental police and invest money for the protection of the environment

Sustainable energy

In manufacturing we use too much energy. For this reason we make sure that at least 25% of our energy consumption comes from sustainable energy sources, mainly photovoltaic energy.

Recycled iron

All the iron and stainless steel scrap go for recycling. The majority of the iron 90%, in an Arte wood-burner comes from scrap that has been re-smelted.

Recycled paper

We make a recycling with the packaging of the raw materials and papers from the offices. We use recycled packaging for our products. We speak about big quantities of paper per year.

Environment and the company

Sewage treatment plant Faithful to its environmental policy ARTE installed a sewage treatment plant for wastewater of the production process. So the water can be used for watering the trees on the factory surroundings.

Περιβαλλοντική Πολιτική